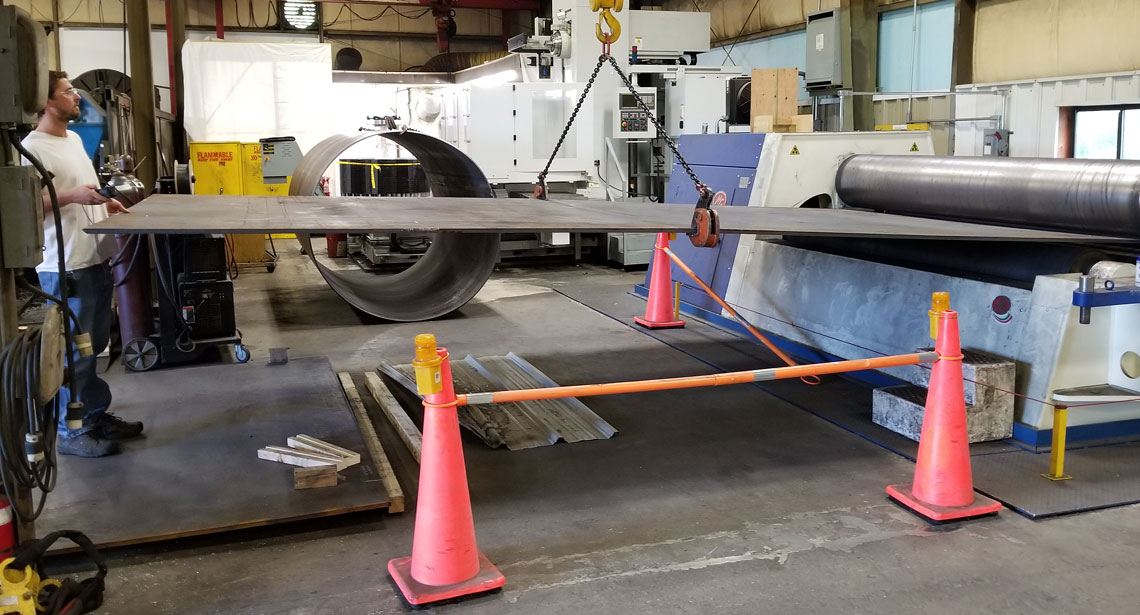

Rolled and Welded Cylinders & Plate Rolling

From an Industry Leader in Large Fabrication and Machining

Winchester Precision Technologies is uniquely prepared to meet all your Rolled and Welded Cylinder and plate rolling requirements, regardless of size or complexity. In addition to rolling and welding we are an ASME code facility for the engineering, design and manufacture of Section VIII Div. 1 “U” stamped pressure vessles.

Our team has put both experience and equipment to the test with the goal of consistently delivering comprehensive plate rolling that can accommodate the most stringent specifications. For every project, Winchester Precision Technologies maintains total quality control to ensure our valued customers receive plate rolled products and rolled/welded cylinders of uncompromised quality.

Plate Rolling Capabilities

- 4 Roll CNC Plate Bending

- Up to 120” wide

- Up to 2-1/2” thk

- CNC 4 Roll Cylinder, Cone and Shape Forming Capabilitiess

- ASME welding and pressure vessel design/manufacture.

- CNC4 roll forming

Plate Rolling for All Materials, Sizes, and Specifications

With the ability to roll and weld alloys ranging from standard and low temperature carbon steels, to stainless steels, high nickel alloys, monels, inconels, hastelloys, and more along with our ASME welding capabilities – we are uniquely suited to meeting a wide range of rolling and welding needs.

Why Winchester?

With repeat customers in a wide variety of industries, Winchester confidently provides plate rolling to meet even the highest standards. Customers consistently choose us for:

- Certified material test reports traceable to the original heat

- Roll Manufacturing & Fabrication capabilities to virtually any type and size.

- ASME pressure vessel fabrication.

- Welders certified to A.S.M.E. Section IX

- Advanced CNC lathes and milling machines

Truly Comprehensive: From the earliest design, to packaging and shipping in our own trucks and personally conduct the scheduling and shipping of our goods.

3D CAD, solid modeling and Finite element analysis: Our experienced staff of engineers utilize Solidworks™ and Autocad™ for 3D or solid model representation of components for machine design and analysis to ensure a final product of un compromised performance and durability.