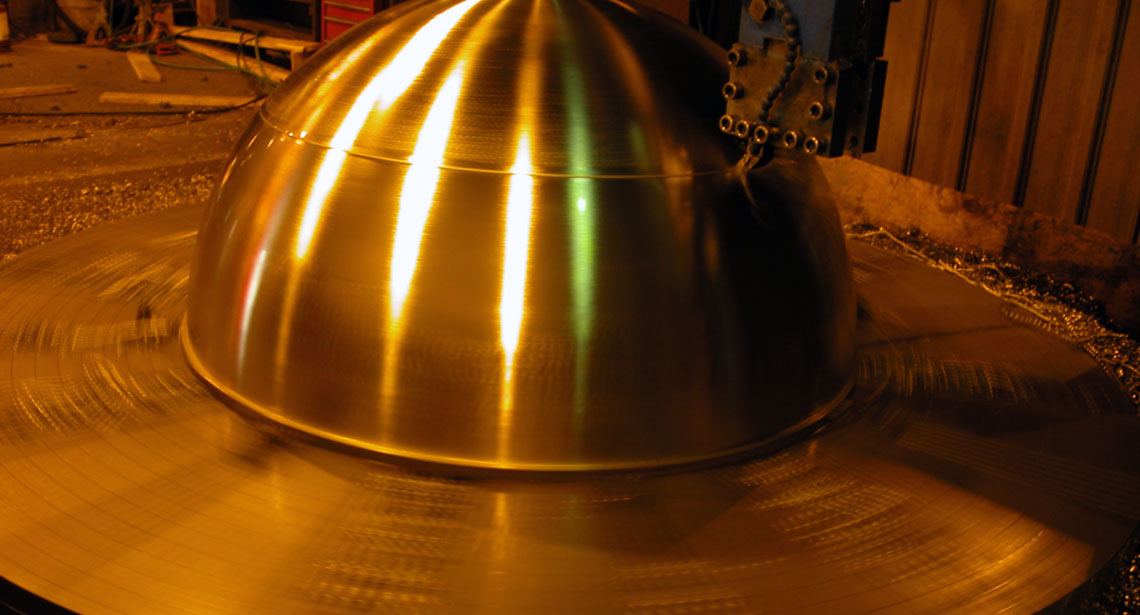

LARGE DIAMETER METAL TURNING AND LARGE MACHINING SERVICES

Focused on Quality, Communication, and Precision

At Winchester Precision Technologies our strength is our manufacturing engineering and our understanding of the steps required to take your large part designs and make them reality.

With extensive large turning capabilities and a reputation for delivering precision, quality, and cost savings on-time, Winchester Precision Technologies has had the opportunity to provide large metal turning for numerous industries.

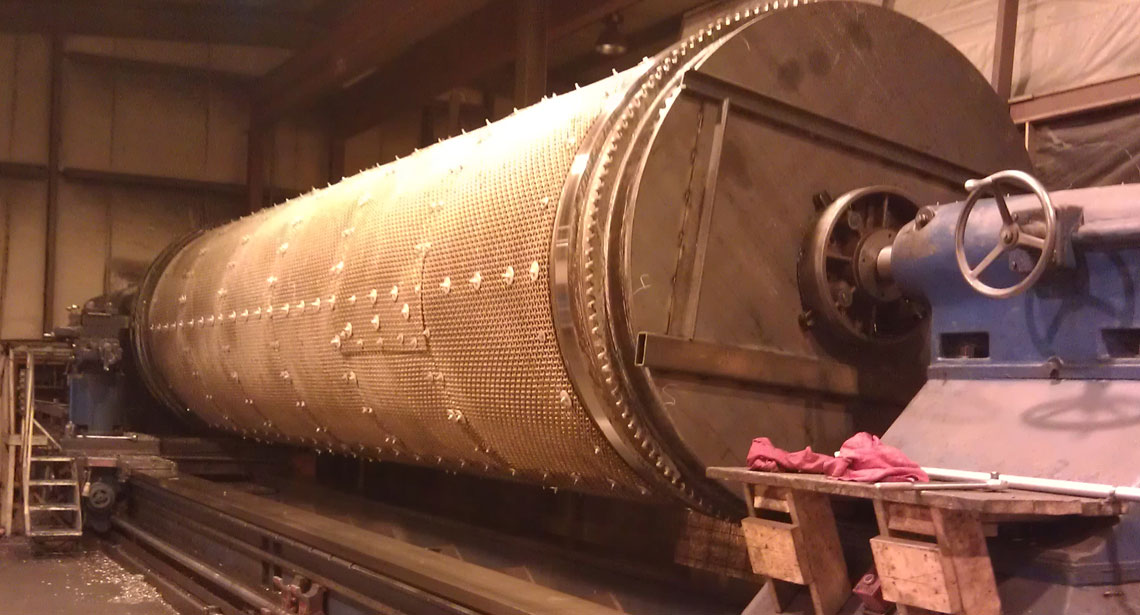

Some of the parts, products, and components our facility delivers include precision rolls, chemical process equipment, power generation components, ship propulsion and large industrial shafts of virtually any size.

When valued customers in any industry need a large metal turning, they trust Winchester to get the job done - for our experience, for our equipment, and for our approach to service.

Large Diameter Turning Capabilities

For large sizes and all alloys

Winchester Precision Technologies leverages our extensive large diameter metal turning experience to provide our customers with innovative machining solutions to overcome the challenges of long roll metal part manufacturing.

Our capabilities include:

- 168”-240" Diameter Vertically

- 120" Tall Vertically

- 570" Long Horizontally

- CMM Inspection

- 12’ Faro Arm, Faro Laser Tracker

- Extensive Milling & Fabrication Capabilities

- Roll Forming Up to 2-1/2” thk. Up to 120” Wide 21” Min. ID

- Lift capacity up to 60,000lbs

- Giant-scale Engine Lathes

Industries Served With Large Turning

- Chemical Process Equipment

- Converting

- Large Industrial Shafting

- Paper, Sheet, and Textiles

- Plastic Film

- Power Generation

- Ship propulsion

- Ship Shafting

- ASME Pressure Vessels

- Defense and National Lab

Advanced Large Turning and Forming Services at Winchester

The engineering team at Winchester Precision Technologies approaches every project with collaboration in mind, beginning with a detailed analysis of product features, which is then translated into specific process design requirements for the manufacture of your custom machinery or products.

At every step of the process, our team will partner with yours to ensure that your custom machinery or parts meet your final specifications.