SUCTION AND VACUUM ROLLS MANUFACTURED WITH QUALITY, AT A COMPETITIVE PRICE

When it comes to the paper and plastic industries, you require performance and reliability that you never need to question.

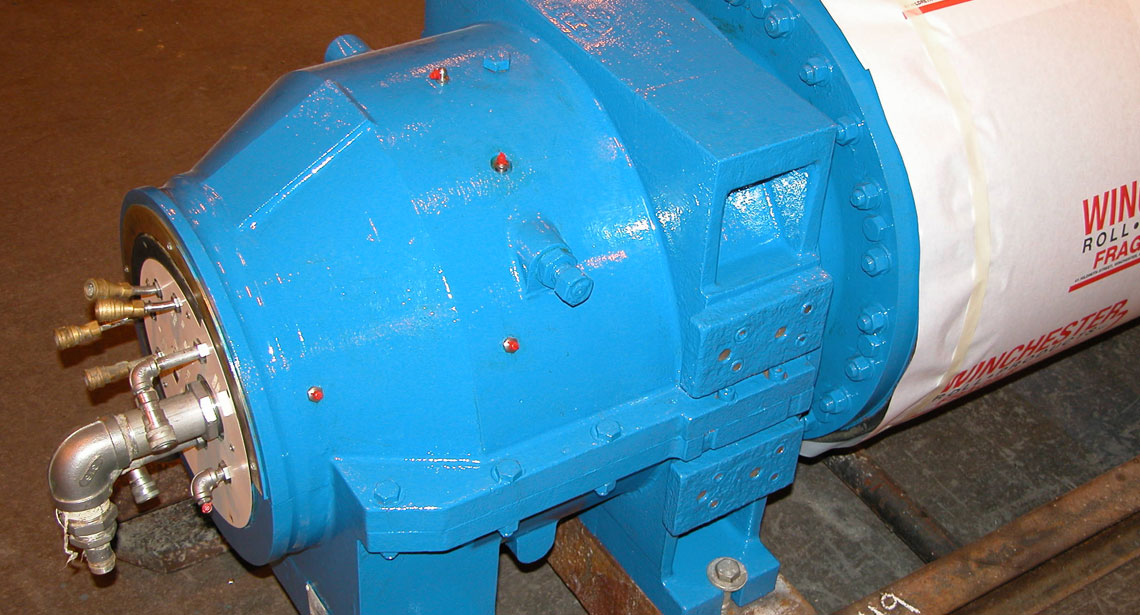

To meet that need, suction and vacuum rolls from Winchester Precision Technologies are manufactured, serviced, and repaired with the best available equipment and decades of experience working directly with industrial rolls of every kind.

Roll Services for Vacuum and Suction Rolls

For rubber covered, bronze, and stainless steel vacuum and suction rolls, our team offers comprehensive services ranging from roll balancing on our 3 plane, computerized dynamic balancer with certified reports, to the manufacturing of an entirely new suction or vacuum roll.

CNC Roll Forming

- Roll Design and Engineering

- Roll Manufacturing

- Grinding

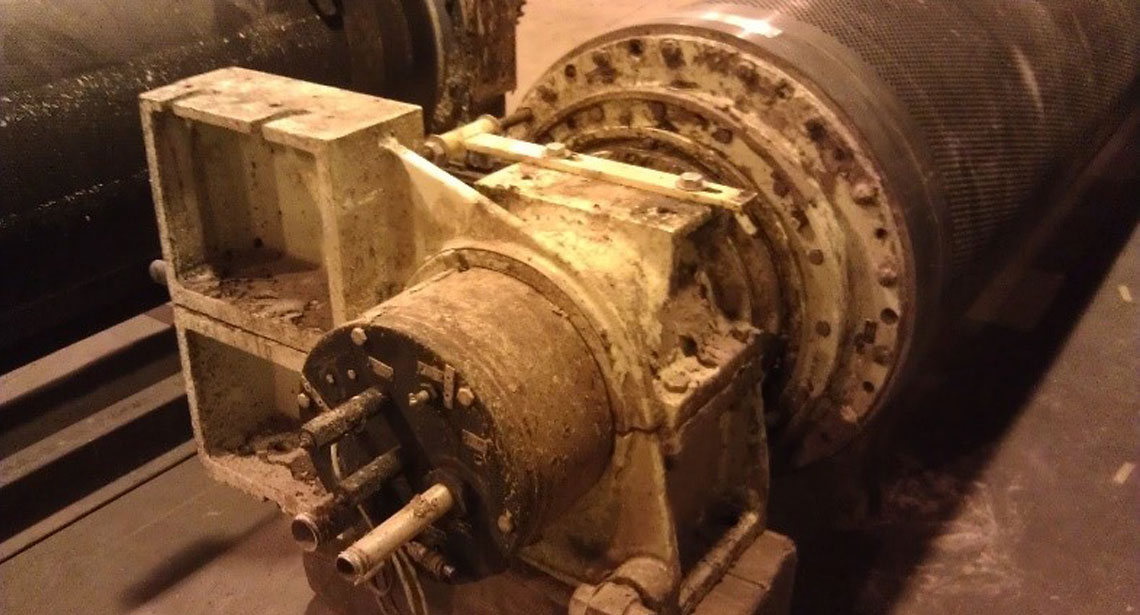

- Repair

- Machining of Replacement

- Multiple Computerized Measuring Machines (12’ Faro Arm, Faro Laser Tracker) for inspection/documentation of existing components

- Roll Balancing

Suction Roll Inspection: Winchester Precision Technologies can provide documented inspection of all critical fits including bearing diameters, housing bores, body bore, seal surfaces, drive diameters, Head fits, Suction boxes, Seal Strips, bore profile, body profile and surface finishes. Non-destructive examination of parts by our ANST Level II Ltd examiner. After inspection the customer is supplied with a full report including recommendation of repair areas of concern and recommended future service frequencies to reduce permanent damage to your roll.

Roll Engineering: Is your roll old and in-need of replacement parts or has your process or product changed and now your rolls are not functioning properly. Let our engineers evaluate your roll/rolls and make recommendations as to what can be done to improve their performance. You can start the process by giving us a call or by filling out our Roll Specification Tech. Form and sending it to us via email or fax.

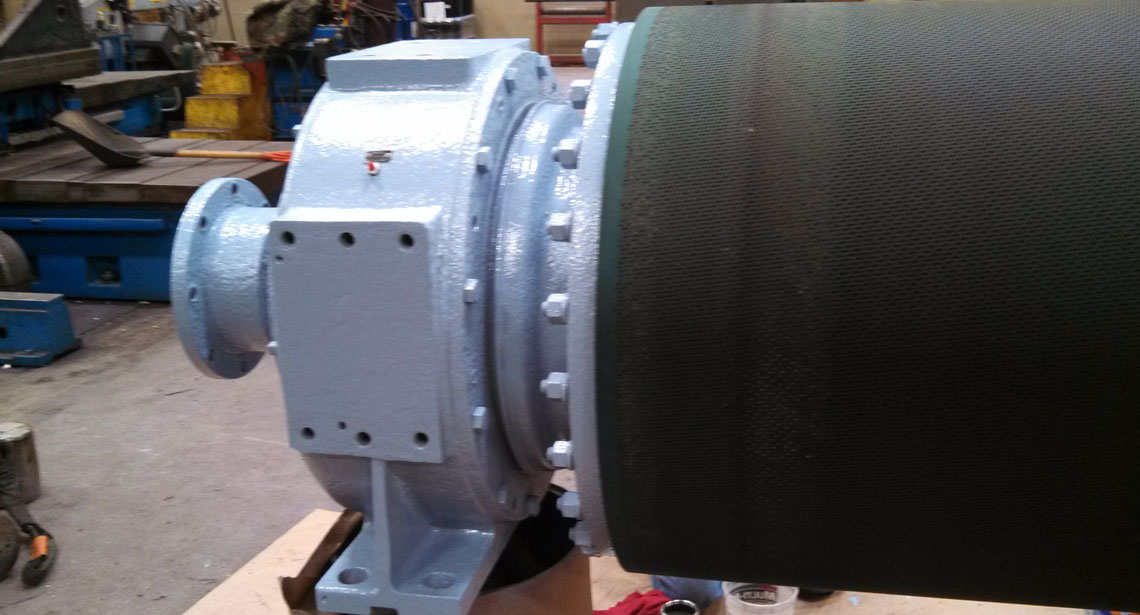

Roll Refurbishment: After inspection and consultation, our team will refurbish your rolls to original or improved specifications and provide certified in-process and final inspection reports when requested. Your finished rolls will be better than new and ready for a long and productive service life.

Service Contracts: For over 30 years, Winchester Precision Technologies has cultivated and maintained enduring collaborative partnerships with our valued customers. Integral to our long-term success is communication and belief that when we work together, we can achieve the outstanding results. We are pleased to provide service options for regular maintenance on your rolls to help reduce cost and ensure products of superior quality.

Types of Suction and Vacuum Rolls

Suction and vacuum rolls serve a number of purposes in the paper, plastic, and textile manufacturing process. Some of the suction and vacuum rolls we frequently work with include.

- Suction breast rolls: used to form the sheet on lightweight paper

- Suction couch rolls: used to remove the water from the sheet. This suction roll is also sometimes used to join multiple ply sheets.

- Suction pickup or vacuum rolls: used to transfer the sheet from surface to surface, usually from the forming fabric to the felt.

- Suction press rolls: most often used to extract water away from the nip and towards the felt

- Suction transfer rolls: used to vacuum a sheet from felt to felt without using an open draw.

- Vacuum rolls: similar to a suction roll, but more frequently used with plastic webs to apply coating to a surface.

- Vacuum chill rolls: a variation of the standard vacuum roll, but with the added ability to transfer heat between the roll and the web